Spitzke-Chromcarbid® (Thin layer chromium)

The "pearl" of the chromium coating family. Thanks to the pearl-like structure and the ionic bond of the chromium via a carbon atom, a coat forms whose adhesion to the base material is greater than the component's solidity. A coating suitable for extreme stress, including long-term exposure, for example in the bearing industry, where it also performs extremely well as a thin layer. In many cases it replaces thick layers of hard chromium.

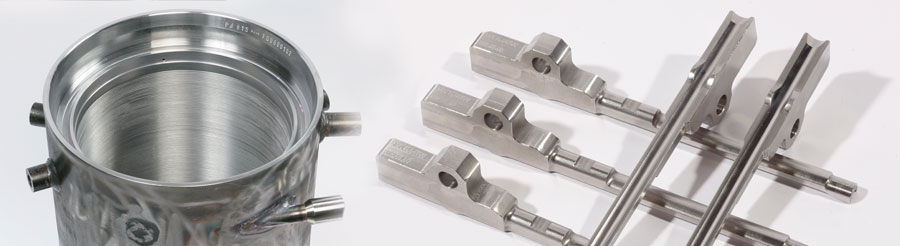

If food or pharmaceutical products come into direct contact with a coating, it need to be very durable - which includes resistance against cleaning and disinfection agents - so that it can't contaminate the products. You need a special permit before using this kind of coating for these applications.

Please contact us if you are interested in acquiring a permit.

Applications