Electroless Nickel

In electroless nickel coating, all the wet surfaces of a component are coated almost uniformly by immersing it in a corresponding bath. The coat has extremely high corrosion and chemical resistance. When subjected to heat treatment, a coat of electroless nickel can become almost as hard as hard chromium, making it the ideal solution for certain applications. Because its thickness is nearly uniform over the entire surface, this coating can also be used to correct measurements in moulds where post-treatment is impossible.

We also coat aluminium and all its alloys.

Applications

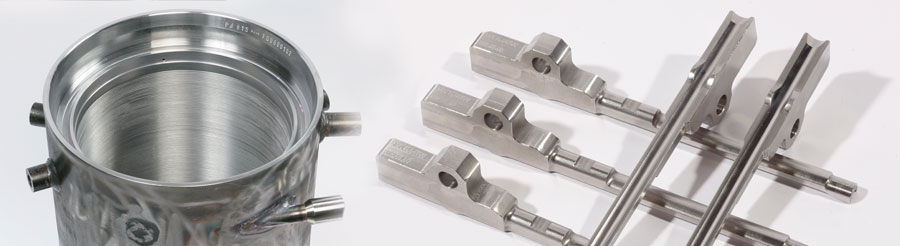

Plate

Even distribution of coating

Aluminium housing